Tecnargilla posticipated to 2021… we don’t !

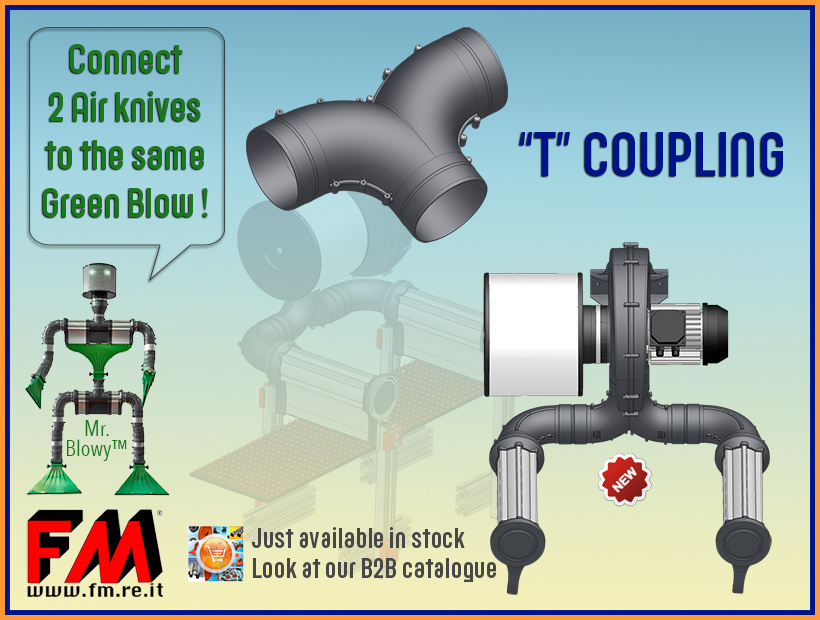

Green Blow Air Line – “T” Coupling

Green Blow Air Line – Tile drying video

Tecnargilla Preview

Filter for Green Blow

Green Blow becomes hydraulic

After the great success of the electric version of Green Blow during last edition of Eima, has been developed the version with hydraulic drive for agricultural applications. We would like to remember the main features of Green Blow: compactness, lightness (only 4,3 kg), high blowing performances di soffiaggio with little motors. Some features of hydraulic version: – Average output air speed 65m/s (with 620mm spout) […]

read more »Tecnargilla 2016′ news

Tecnargilla 2016 Preview

Green Blow – a breath of News

Green Blow is the new FM centrifugal blower specially designed and built for the use on ceramic lines, in particular for cleaning and cooling tiles at the input of the digital printers. Green Blow can however also be used in other industrial sectors when it is necessary to cool/clean items and/or devices. An analysis of market needs and the […]

read more »